Coupling & Shaft Alignment – Course Topics

1. Fundamentals of Couplings & Alignment

-

Importance of couplings and alignment in rotating equipment reliability

-

Types of misalignment: angular, parallel, axial, and combination

-

Effects of misalignment on bearings, seals, and overall equipment life

-

Industry standards and best practices

2. Coupling Types & Applications

-

Rigid couplings: sleeve, clamp, flange

-

Flexible couplings: elastomeric, gear, grid, disc

-

Specialty couplings: fluid, magnetic, diaphragm

-

Selection criteria based on operating conditions and equipment type

3. Shaft Alignment Principles

-

Alignment tolerances and specifications

-

Soft foot detection and correction

-

Thermal growth considerations during alignment

-

Alignment of vertical and horizontal machines

4. Alignment Methods & Tools

-

Traditional methods: straightedge, feeler gauges, dial indicators

-

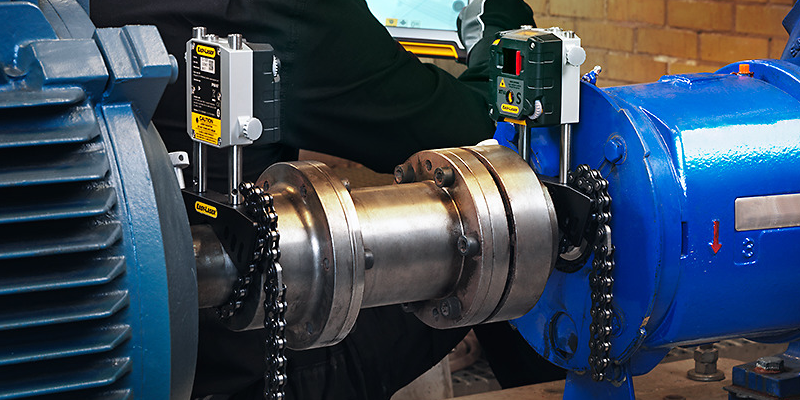

Modern methods: laser alignment systems

-

Step-by-step alignment procedures

-

Documentation and reporting of alignment results

5. Maintenance & Reliability Practices

-

Preventive maintenance for couplings and alignment systems

-

Predictive diagnostics: vibration analysis, thermography, oil analysis

-

Balancing and alignment integration

-

Case studies of failures due to poor alignment

6. Troubleshooting & Corrective Actions

-

Identifying symptoms of misalignment and coupling wear

-

Root cause analysis of coupling and alignment failures

-

Corrective measures and repair techniques

-

Reliability improvement programs

7. Safety & Environmental Considerations

-

Safety protocols during alignment and coupling maintenance

-

Handling high-speed rotating equipment safely

-

Environmental impacts of poor alignment (energy loss, emissions)

-

Compliance with industry standards and regulations

- المعلم: motaz mohamed